For DC spot welding/fusing IP series

- ◆Fast current rises due to primary constant current.

- ◆4kHz high speed adaptive feedback.

- ◆Simple operation by a few operating buttons.

- Up to 63 weld schedules to support multi welding conditions

- ◆Communication facility is equipped on standard.

- ◆Built-in welding transformer.

◆The IP100C and IP200V have built-in welding transformers.

- ◆Beautiful, easy-to-view screen display

High-brightness LCD makes it possible to see the screen clearly even in the dark.

- ◆Automatic display switching

Normally, the setting screen is displayed, but once the welding current starts to flow, the screen will be automatically switched to current monitor display.

- ◆Sheet panel that withstands dust and oil mist

Even if the sheet panel gets soiled, it can be cleaned up easily to maintain a beautiful appearance at all times.

Using an externally connected PC, weld schedules can be read out and reprogrammed. In addition, monitoring data and error codes can be viewed from the PC

- ◆Datacom

| For spot welding (Built-in transformer type) | For spot welding | ||||

|---|---|---|---|---|---|

| Model | IP-100C | IP-200C | IP-400B | ||

| Power requirements *1 | 180 to 240VAC, 50/60Hz, Three phase | 3-phase 180 to 240VAC 50/60Hz | |||

| Control frequency | 4kHz | 4kHz | |||

| Maximum output current | - | 200A | |||

| Maximum weld current | 1300A | 2500A | 5000A (when used with IT-513B) | ||

| Rated capacity | 1.4kVA | 5.3kVA | 15kVA (when used with IT-513B) | ||

| Control method | Primary constant current | Primary constant current | |||

| Welding schedules | 63schedules | 63schedules | |||

| Timer setting | SQ | 0000 - 9999ms *2 | 0000 - 9999ms *2 | ||

| RISE1, 2 | 00 - 49ms | 00 - 49ms | |||

| WELD1, 2 |

|

|

|||

| COOL | 00 - 99ms | 00 - 99ms | |||

| HOLD | 000 - 999ms *2 | 000 - 999ms *2 | |||

| Welding current setting (HEAT1,2) | 100 - 1300A | 400 - 2500A | 0.80 - 5.00kA | ||

| Mass | 10kg | 12kg | 9.5kg | ||

- *1: Set at the factory

- *2: When the software switch (SW5) setting is 1, SQ and HOLD function.

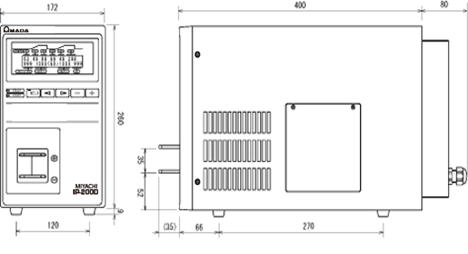

- ◆IP-100D

- ◆IP-200D

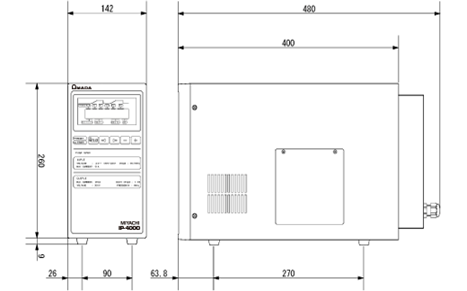

- ◆IP-400D

| Power requirements | 180 to 240VAC |

|---|---|

| Model | IT-513B |

| Rated capacity | 15kVA |

| Rated primary voltage | 300V |

| No-load secondary voltage | 10.0V |

| Input frequency | 4kHz |

| Maximum output current | 5000A |

| Duty factor (@50ms) | 4.5% |

| Cooling method | Air cooling |

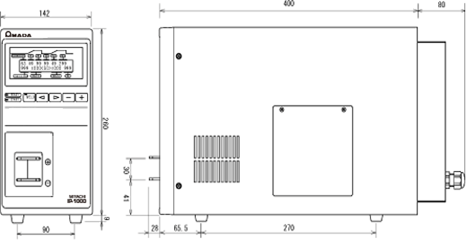

| Dimensions and mass | 195W x 400D x 185H mm / 15kg |